Breeding and Feeding Systems

Automatic Channel Feeding System

Quality Guaranteed

Fast Delivery

2 Year Warranty

24/7 Support

Request a quote for pricing

Free Shipping<br>Nationwide

Easy Return<br>Within 14 Days

Secure Shopping<br>256 Bit SSL

Product Description

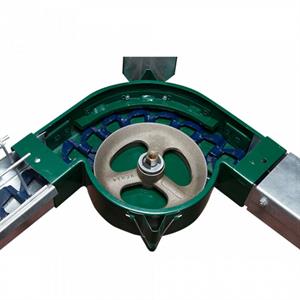

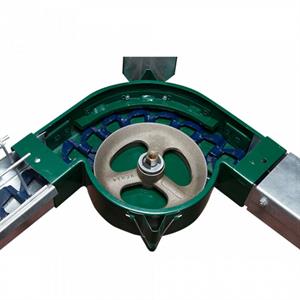

GENERAL INFORMATION Feeder Channel This highly practical feeder channel, with its special design and wide opening, is manufactured from 1mm thick galvanized sheet metal. (Channel lengths are 3 m.) Feeder Corner The ductile cast iron channel feeder and corner, which requires no oiling or maintenance, is one of the most important parts of the line. The 90-degree corner operates smoothly even at high speeds thanks to its heat-treated guide rail and self-lubricating shaft bearing. It is suitable for both foot-mounted and lifting automatic channel feeder systems. It features both an adjustable height foot connection system and lifting handles for hanging feeders. Feeder Chain Our chain, made from special material, is completely free of kinking, elongation, and slack. It has a tensile strength of up to 12 kN. It is offered in 2 types to suit our customers' preferences. It works in harmony with the corner and motor gear groups. It is resistant to high speeds. Channel Feeder Lifting System In the lifting feeder system, the motor operates under a scissor mechanism and is connected to the channel bridge plates, corners, and hopper via pulleys and steel cables. The motor is equipped with brakes and a double gearbox, reducing the speed to 5 rpm and transmitting the system's smooth and slow movement through a 50 mm diameter pipe to the cable winding mechanisms. Four bearing wheels made of special cheddar material are fixed between each pulley pipe to keep it level and prevent sagging. Up and down movement is adjusted on the control panel. Grill The channel top grill is designed to ensure that animals eat even amounts of feed regularly. It does not change between freestanding and lifting systems. It has a shock wire system. It is impact resistant and does not flex. The grill spacing is made in different sizes depending on the type of animal in the poultry house. Motor Group This is the mechanism that drives the channel feeding system. The motor group is connected to the system with gears. The gear connected to the motor shaft drives the chain. The feed hoppers are manufactured to be suitable for both lifting and standing systems. The purpose of this production method is to avoid any problems when switching between standing and lifting systems. Motor Group and Gear System Single-speed motors are used in lifting automatic channel feeder systems. Double-speed motors are used in standing automatic channel feeder systems. Feed Hopper This is the unit where the product first enters the feeding line from the silo. From this point, the feed is distributed along the line using chains made of special materials. The size of the feed hopper varies according to the farm capacity. More than one outlet option is available depending on the need. Furthermore, the feed hopper is manufactured as a standing system in standing automatic channel feeder systems, and as both a hanging and standing system in lifting automatic feeding systems. The same feed hopper can be used in both systems. Capacity: Between 240-600 kg. Feeder Channel Legs and Bridge The height-adjustable channel legs (bridges) used in automatic leg-operated channel feeding systems are made of galvanized sheet metal and have a thickness of 2 mm. They are fully compatible with the leg system and can also be used with a lifting channel feeder system by attaching a hanging bracket. Nest Box Our nest boxes, whose bodies are made of galvanized sheet metal, have wooden parts for the animals to step on. The footboard is movable upwards to prevent animals from entering the nest box at night. This prevents animals from entering. The top is sloped to prevent animals from perching inside. Each nest box has a capacity of 3-4 animals. Nest boxes with bedding (sawdust) inside will also prevent heat loss. The nest box should be placed in a secluded and dimly lit area of the poultry house whenever possible. Control Panel The switchgear used in ALFAN electrical panels is from the Siemens brand. The control panel's outer casing is detachable and reassemblable, and is coated with static paint. The motor that drives the chain in the automatic lifting channel feeder system is single-speed, so the channel feeder system is activated by a start-stop button. On the lifting line, the motor operates the line up and down. Control buttons manage the up-down movement of the line. Thanks to safety switches, the up and down distance controls are performed automatically.General Specifications

Category

Breeding and Feeding Systems

Status

Active

Views

94 times

Technical Details

Info

No technical details added

Thinking of a Custom Project?

Our expert team is ready to help you. Contact us now for product selection, technical support or price quote.